Author: Denis Avetisyan

A new deep-learning approach, combined with advanced holographic microscopy, is providing unprecedented insight into the identification and characterization of microscopic plastic fibers in our environment.

Polarization-resolved digital holography and explainable AI achieve 96.7% accuracy in identifying microplastic fibers by revealing key optical features.

Accurate identification of microscopic plastic pollution remains analytically challenging despite its growing environmental impact. This is addressed in ‘Explainable deep-learning detection of microplastic fibers via polarization-resolved holographic microscopy’, which presents a novel framework leveraging polarization-resolved digital holography and deep learning for classifying microplastic and natural fibers. The approach achieves 96.7% accuracy while revealing that eigenvalue-ratios derived from the Jones matrix are dominant predictors of material type, providing a physically interpretable basis for classification. Could these polarization-based optical fingerprints offer a broadly applicable solution for automated microplastic identification and environmental monitoring?

The Pervasive Threat of Microplastic Fibers: A Growing Ecological Risk

Microplastic fibers have emerged as a ubiquitous and concerning pollutant, infiltrating ecosystems globally. These minute particles, often shed from synthetic textiles during washing, but also originating from sources like industrial processes and tire wear, are remarkably persistent in the environment. Their small size allows them to be readily ingested by a wide range of organisms, from zooplankton to larger marine animals and even terrestrial wildlife, potentially disrupting feeding behavior, reducing energy reserves, and causing physical harm. The pervasive nature of these fibers means they’ve been detected in remote locations – from the deepest ocean trenches to mountaintop snow – highlighting a substantial ecological risk that demands further investigation into their long-term impacts on both wildlife and human health.

Current techniques for characterizing microplastic fibers present substantial challenges to environmental monitoring. Historically, identification has relied heavily on visual sorting under microscopes, a process that is not only exceedingly slow and demands significant analyst time, but is also prone to subjective error and limited by the optical resolution of the equipment. Moreover, differentiating between naturally occurring fibers and those originating from plastic pollution requires specialized and often destructive analytical methods, such as Raman spectroscopy or thermal analysis, further increasing the complexity and cost of accurate quantification. This inability to rapidly and reliably assess microplastic fiber concentrations hinders comprehensive environmental studies and effective pollution mitigation strategies, necessitating the development of more efficient and precise analytical tools.

Unveiling Fiber Characteristics with Advanced Optical Microscopy

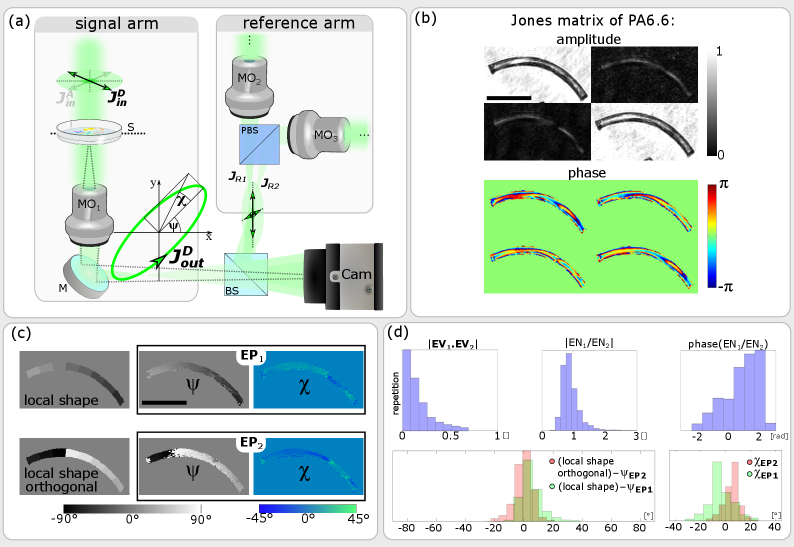

Digital Holographic Microscopy (DHM) provides three-dimensional characterization of microplastics in liquid suspensions without requiring physical sectioning or staining. Unlike traditional 2D microscopy techniques, DHM reconstructs a complete volumetric dataset from the interference pattern of light, enabling the measurement of particle size, shape, and orientation in situ. This non-destructive approach avoids potential alterations to the sample caused by preparation methods and allows for repeated measurements on the same particles over time. Furthermore, DHM overcomes limitations associated with conventional methods like light scattering, which can be inaccurate for small or irregularly shaped particles, by directly imaging the microplastic’s three-dimensional structure. The technique is particularly suited for analyzing microplastics in complex aqueous matrices, such as environmental water samples, without the need for laborious and potentially biasing separation procedures.

Polarization-Resolved Digital Holography (PRDH) builds upon standard Digital Holographic Microscopy by incorporating polarization-sensitive optical components. This enables the measurement of light polarization state changes as light interacts with the sample. Different materials exhibit unique birefringence and dichroism, altering the polarization of transmitted or reflected light in material-specific ways. By analyzing these polarization changes, PRDH allows for the differentiation of fiber types based on their composition and orientation, even those with similar physical dimensions. This technique improves fiber identification accuracy, particularly in complex mixtures, and provides quantitative data regarding material properties beyond simple size and shape measurements.

Quantifying Fiber Signatures: Feature Extraction and Deep Learning

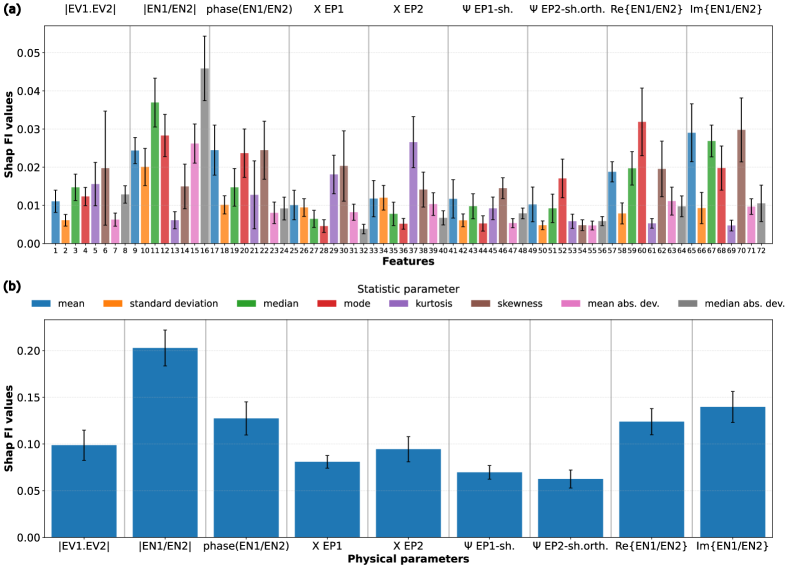

Statistical Feature Extraction processes data acquired via Polarization-Resolved Digital Holography to generate a quantifiable Feature Vector for each analyzed microfiber. This process involves calculating statistical measures – including mean, standard deviation, skewness, and kurtosis – from the polarization characteristics of the backscattered light. These characteristics, derived from the Stokes parameters, describe the polarization state of the light and are sensitive to the microfiber’s material composition and geometry. The resulting statistical values are then compiled into a numerical Feature Vector, effectively representing the polarization ‘signature’ of each fiber and serving as input for subsequent classification algorithms.

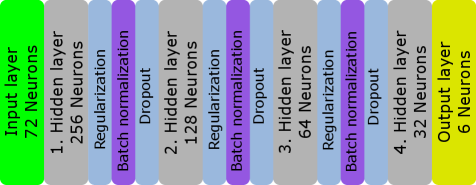

Following statistical feature extraction, a Fully Connected Deep Neural Network serves as the classifier for microplastic fiber types. This network architecture consists of multiple fully connected layers enabling complex pattern recognition within the Feature Vectors. To prevent overfitting and enhance generalization performance, Batch Normalization layers are incorporated to normalize the input to each layer, while Dropout layers randomly deactivate neurons during training. This regularization technique forces the network to learn more robust and less interdependent features, improving its ability to accurately classify fiber types such as Polyamide 6, Polyethylene Terephthalate, Polyamide 6.6, and Polypropylene.

Classification accuracy was used to evaluate the deep learning model’s performance in distinguishing between microfiber types, specifically Polyamide 6, Polyethylene Terephthalate, Polyamide 6.6, and Polypropylene. Rigorous testing yielded an overall accuracy of 96.7% when assessed against validation data, indicating the model’s ability to generalize to unseen samples. Further evaluation on the complete dataset resulted in an improved accuracy of 98.6%, demonstrating robust performance and effective classification of the targeted fiber types.

Beyond Accuracy: Unveiling the ‘Why’ with Explainable AI

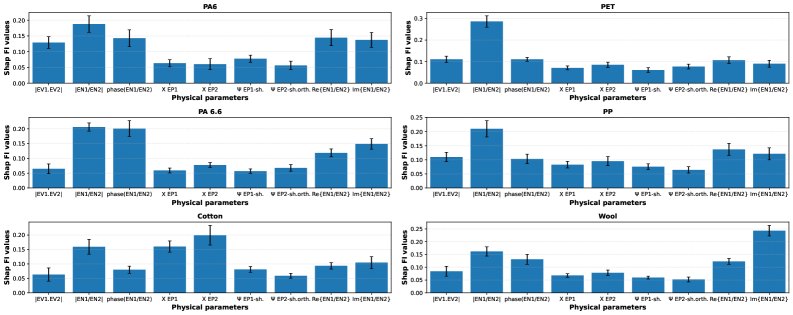

The intricacies of deep learning models often obscure the reasoning behind their classifications. However, utilizing SHAP (SHapley Additive exPlanations) values allows for a quantifiable dissection of a model’s decision-making process. This technique assigns each input feature a value representing its contribution – positive or negative – to the prediction. In the context of microplastic fiber classification, SHAP values reveal which optical properties – such as size, shape, and spectral characteristics – most strongly influence the neural network’s categorization of different fiber types. By pinpointing these key features, researchers gain a deeper understanding of why the model makes specific classifications, moving beyond simply knowing that it classifies correctly. This transparency is crucial for validating the model’s behavior, identifying potential biases, and ultimately building trust in its ability to accurately assess and monitor environmental contamination.

The capacity to dissect the decision-making process of artificial intelligence models extends beyond simple accuracy metrics, offering crucial revelations about the inherent characteristics of microplastic fibers. By pinpointing which optical properties – such as specific wavelengths of reflected light or subtle variations in polarization – most strongly influence fiber classification, researchers gain a deeper understanding of the materials themselves. This knowledge isn’t merely academic; it directly informs material science, allowing for improved identification of polymer sources and degradation pathways. Simultaneously, it bolsters pollution monitoring strategies, enabling more precise assessment of environmental contamination and the development of targeted mitigation efforts based on fiber type and origin. The ability to link specific optical signatures to particular plastics facilitates a more nuanced and effective approach to tackling the growing problem of microplastic pollution.

The study demonstrates that a remarkably high classification accuracy – reaching 93.3% – can be achieved utilizing only features derived from Eigen-Normalization (EN). This finding underscores the potent discriminatory power of EN-based characteristics in distinguishing between different types of microplastic fibers. By focusing on these mathematically derived properties, the model effectively captures subtle yet critical differences in fiber composition and structure, obviating the need for more complex or computationally expensive feature sets. This streamlined approach not only enhances the efficiency of microplastic identification but also suggests that the underlying mathematical properties encoded within EN features are intrinsically linked to the physical characteristics defining each fiber type, offering a powerful means of automated material classification.

Accurate identification of microplastic fibers, facilitated by advanced analytical techniques, presents a crucial step towards comprehensively evaluating environmental contamination levels. This capability extends beyond simple detection, enabling researchers to pinpoint the specific polymer types and characteristics prevalent in different environmental niches – from marine sediments to freshwater sources and even atmospheric particles. Coupled with feature importance analysis – which reveals the specific optical properties driving classification – this approach doesn’t just quantify pollution, but also informs the development of targeted mitigation strategies. Understanding which fiber characteristics are most indicative of specific plastic sources, for instance, can help trace pollution back to its origins and guide preventative measures. Furthermore, the insights gained can contribute to the design of more effective filtration systems and biodegradable alternatives, ultimately reducing the long-term impact of plastic pollution on ecosystems and human health.

The pursuit of automated classification, as demonstrated by this work on microplastic fiber detection, often prioritizes performance metrics over mechanistic understanding. This research, however, attempts to bridge that gap by not merely identifying fibers, but elucidating how the deep learning model arrives at its conclusions via polarization-resolved holographic microscopy. This aligns with Kapitsa’s observation: “It is in the interests of science that we should make every effort to understand nature as she is, and not as we would like her to be.” The model’s reliance on specific optical features – the Jones matrix parameters, in this case – offers a level of transparency frequently absent in ‘black box’ deep learning systems, moving beyond simple prediction toward genuine insight. The focus on explainability is crucial; otherwise, data merely becomes another set of assumptions, ventriloquized by opaque algorithms.

Where Do We Go From Here?

The demonstrated accuracy in identifying microplastic fibers, while notable, should not be mistaken for resolution. The system excels at classifying what it has already seen, a feat common to many supervised learning approaches. The true challenge lies in generalization – the ability to reliably detect novel fiber types, varying degradation states, and those embedded within complex environmental matrices. Robustness testing, particularly with deliberately ambiguous samples, will be critical; correlation is suspicion, not proof, and a 96.7% accuracy figure offers limited comfort without rigorous adversarial validation.

Future work must move beyond feature extraction post hoc. The Jones matrix formalism provides a powerful framework, but its full potential remains largely untapped. Integrating physical modeling – simulating light interactions with fibers of varying geometries and compositions – could yield a more interpretable and, crucially, more predictive system. Such a hybrid approach might mitigate the need for extensive training datasets, a persistent limitation in this field.

Ultimately, the pursuit of ‘explainable AI’ risks becoming an exercise in justification, rather than understanding. The goal should not be to simply identify which optical features drive classification, but to determine why those features are indicative of microplastic fibers, and whether those indicators hold true across diverse and ecologically relevant conditions. Only then can this technology move beyond a laboratory curiosity and become a genuinely useful tool for environmental monitoring.

Original article: https://arxiv.org/pdf/2601.15769.pdf

Contact the author: https://www.linkedin.com/in/avetisyan/

See also:

- 39th Developer Notes: 2.5th Anniversary Update

- The 10 Most Beautiful Women in the World for 2026, According to the Golden Ratio

- TON PREDICTION. TON cryptocurrency

- Gold Rate Forecast

- Bitcoin’s Bizarre Ballet: Hyper’s $20M Gamble & Why Your Grandma Will Buy BTC (Spoiler: She Won’t)

- Nikki Glaser Explains Why She Cut ICE, Trump, and Brad Pitt Jokes From the Golden Globes

- Dividends: A Most Elegant Pursuit

- Venezuela’s Oil: A Cartography of Risk

- AI Stocks: A Slightly Less Terrifying Investment

- Chipotle & Sweetgreen: A Market’s Quiet Bloom

2026-01-25 11:16